Rumored Buzz on A1 Professional Asphalt & Sealing Llc

Some Known Questions About A1 Professional Asphalt & Sealing Llc.

Table of ContentsThe 6-Minute Rule for A1 Professional Asphalt & Sealing LlcThe Best Guide To A1 Professional Asphalt & Sealing LlcAll About A1 Professional Asphalt & Sealing LlcA1 Professional Asphalt & Sealing Llc Things To Know Before You Get ThisThe 10-Second Trick For A1 Professional Asphalt & Sealing Llc

They likewise enable the possibility of field check and remove the opportunity of sampling mistakes where the asphalt being used was not the like obtained by the testing lab. Simon Hesp, Queens College (Kingston, Ontario) The TFHRC group will soon submit to AASHTO the draft examination methods that transportation companies can use to evaluate for the existence of REOB in asphalt blends.is a senior research study chemist on the Pavement Materials Group in FHWA's Office of Facilities Research Study and Advancement and Federal laboratory supervisor for the chemistry laboratory at TFHRC. He is an other of the Royal Society of Chemistry in the United Kingdom and a Chartered Drug store. For more details, contact Terence Arnold at 2024933305 or .

Crack filling up is when warm sealer is used to fill splits in pavement to avoid water from doing any longer damage. The sealer will certainly abide by the asphalt, keeping water and other natural environments from penetrating and exploiting the weakness in your pavement. One of the largest blunders people make when it comes to splits in their pavement, is waiting too long to get them filled.

Getting My A1 Professional Asphalt & Sealing Llc To Work

Sealcoating leaves your pavement looking streamlined and dark. This is the ideal service if you are searching for an easy method to improve the look of your asphalt and safeguard it from the aspects. Prolongs life of sidewalk Accelerates the melting of snow and ice Decreases long-term repair prices Shields pavement from oxidation, oil, chemical spills and water infiltration Improves appearance of building Milling is the process of getting rid of the leading layer of asphalt without disturbing the underlying subbase.

Milling can be completed at a fraction of the expense of a full reconstruction due to the fact that only the leading layer is eliminated and changed. https://ameblo.jp/a1asphaltseal/entry-12849151704.html. The whole procedure can be finished in a relatively brief amount of time. Inexpensive Quick job conclusion Recycling of old material Patching is the procedure of filling out pits

The Greatest Guide To A1 Professional Asphalt & Sealing Llc

All particles should be gotten rid of, occasionally there may even be plant jabbing with which must be disposed of from the root. asphalt repairs. Asphalt needs a strong base, otherwise, you'll just have extra troubles in the future. The type of asphalt utilized to load splits will depend on the weather condition and dimension of the pocket, usually warm or cool mix asphalt will be utilized

Depending upon the size of the gap, various equipment or tools can be made use of for this. An asphalt overlay can be thought of as a large patching job over a stretch of asphalt. Overlay is commonly made use of when existing asphalt is revealing some indicators of breaking and craters, however not fairly sufficient damage to warrant a complete substitute.

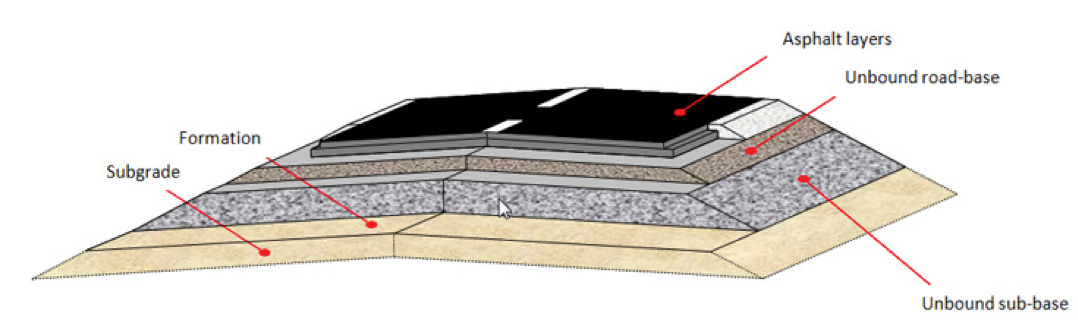

The sub base is the bottom a lot of layer, it will certainly be supporting your new pavement. A proof roll is a test to be sure the underlying surface is strong enough to sustain the brand-new asphalt.

A Biased View of A1 Professional Asphalt & Sealing Llc

It's never ever also late to learn something brand-new, and when important source it concerns asphalt sidewalk setup, there are numerous things that property owners, industrial homeowner, and district workers might not be mindful of. At Wolf Paving, we are Milwaukee, Oconomowoc and Madison asphalt paving specialists in who take pride in educating individuals about every little thing asphalt it's our enthusiasm.

The initial step in the asphalt installation process is to eliminate the existing surface area, whether it is asphalt, concrete or pavers. Demolition and removal is completed using heavy equipment, including small bobcats and forklifts and when required, front loaders and big dump trucks. Debris is then gotten rid of. At Wolf Paving, we reuse the old asphalt and concrete in our asphalt plants, transforming degrading waste right into strong, functional brand-new asphalt.

The below base offers a steady surface area to support new sidewalk. The below base is a frost obstacle to help decrease winter months damages as a result of cold and thawing. During the setup, base density, base security, and compaction are necessary steps. If the below base is not properly compressed, the asphalt surface on the top will certainly not give years of toughness.

The Best Strategy To Use For A1 Professional Asphalt & Sealing Llc

Wolf Paving has likewise pioneered a new procedure called raking. This procedure involves undercutting the sub base, yet rather of removing every one of the soft clay and dirt, it is instead combined with included accumulation to boost the toughness of the compromised areas - a-1 asphalt. When the sub base is laid and any kind of soft locations are identified and fixed, it is time to include the binder